Baton Rouge Concrete Contractors’ Toolbox: Must-Have Tools and Equipment

A secret to a wonderful concrete project—whether it is a concrete driveway, pathway, patio, step, foundation, residential, or commercial—lies not only in the skills of Baton Rouge Concrete Contractors but also in their battle gear when facing the challenges in achieving precision and excellence in concrete construction. This essential toolkit is crucial for Baton Rouge Concrete Contractors. If you are wondering about the necessary tools and equipment in concrete construction, here are the essentials every Baton Rouge concrete contractor should have in their arsenal to ensure efficiency, accuracy, and outstanding results.

Concrete Mixers

These are essential especially if you are constructing large-scale projects as they require a faster concrete mixing process. Although it is possible to mix concrete with bare shovels, it will take more time and can only mix a small amount, which makes the process much longer. On the other hand, concrete mixers offer a more even and consistent concrete mix, which is crucial for the integrity and durability of a concrete project. You can use a portable mixer for small to medium-sized projects, and truck-mounted mixers for handling larger concrete volumes.

Screeds

Screed is a necessary tool that helps Baton Rouge concrete contractors to level the surface and fill the low spots of the concrete. They are for the initial leveling and smoothing phase and are usually a long, straight-edge tool that is dragged across the top to remove excess materials. There are many types of screeds such as manual screeds, which can be operated by hand and are suitable for small to medium projects, and power screeds, which produce vibrations to level the concrete with more precision and are the best option for larger-scale projects. Experts in concrete such as Baton Rouge concrete contractors use their skills to achieve the desired concrete surface, regardless of the type of screeding tool used. But if you consider yourself an amateur, it is best to determine your skill level when choosing the right type of screed is suitable.

Bull float

After screeding the concrete surface, it is also essential to push down aggregate and bring water to the surface with the use of bull floats. Screeds can effectively level the concrete surface, but they leave imperfections and ridges that bull floats can efficiently remove. This tool is usually used before the concrete becomes fully set so that any imperfections are smoothed out early in the surfacing process.

Trowels

These are important for the final finishing of the concrete. While screeds can level and fill the low spots, and bull floats smoothen the imperfections and ridges of the concrete surface, trowels can make it smoother and fine-tune after leveling with screeds and polishing with bull floats. You can use hand trowels for smaller and more detailed work, and power trowels also known as “float” or “helicopter” for larger surfaces, providing a quick and efficient smooth finish.

Concrete Edger

From the name itself, they are used to mold the concrete surface to become rounded or beveled edges. This elevates the design of concrete surfaces while preventing them from chips and cracks along the edges—which are prone to these damages. It comes in many sizes and shapes to allow Baton Rouge concrete contractors and other concrete professionals to create custom edges that can match the specific concrete designs—whether for aesthetics or durability reasons—of each project.

Concrete Vibrators

If the concrete surface is not installed properly, there is a tendency that accumulate air pockets which can weaken the concrete, resulting in cracks and other structural issues over time. That is why Baton Rouge concrete contractors use concrete vibrators to eliminate these destructive air pockets and to ensure that the concrete is well-compacted. It comes in different types such as internal vibrators which are inserted directly into the concrete, and external and surface vibrators which are used outside of the framework.

Measuring and Marking Tools

Precision and accuracy are difficult to achieve without the tools and equipment needed to measure them. Baton Rouge concrete contractors utilize a variety of tools, from basic to modern such as tape measures, laser levels, chalk lines, and paint markers to achieve the right measure of concrete to all forms and dimensions.

These are very essential in preventing costly mistakes and ensuring that the construction process stays on track.

Concrete Saw

Concrete saw is essential, especially for large-scale concrete projects and for repairs and modifications. It is used to cut expansion joints in hardened concrete to help control where cracks appear and very useful for cutting through concrete when repairs and modifications are required. Concrete saws also have a variety of types such as handheld concrete saws, best for smaller cuts, and walk-behind saws which are ideal for larger and more demanding jobs.

Wheelbarrows

This tool is handy in transporting batches of concrete, tools, and materials around the construction site, especially where larger machinery cannot access it due to their immovability. If you are starting your project, this is a versatile that every Baton Rouge concrete contractor needs.

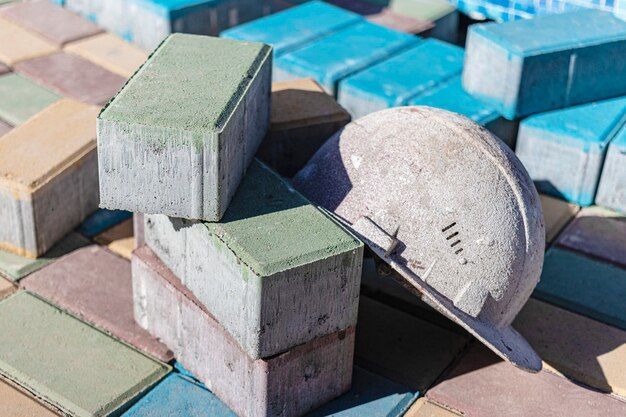

Protective Gear

Last but definitely not least, protective gear as all Baton Rouge concrete contractors should prioritize safety. It is crucial to be equipped with gear such as gloves, safety glasses, hard hats, and steel-toed boots. Accidents can happen anytime, especially when handling heavy tools, operating powerful equipment, or working with materials of all sizes. Note that when starting a concrete project, it is best to prevent potential accidents before injuries happen.

These tools and equipment are essential, whether you’re a seasoned professional or just starting your career, for achieving top-notch results and staying competitive in the construction industry. If you are in Baton Rouge and need expert concrete services,

contact us now so we can help you out.